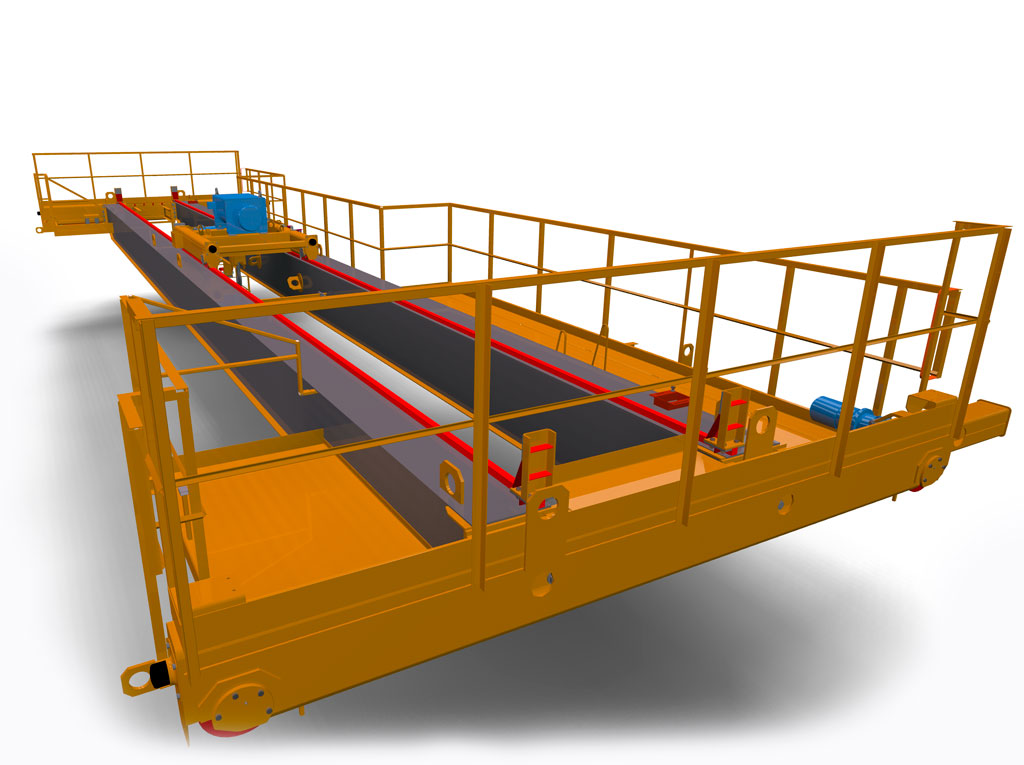

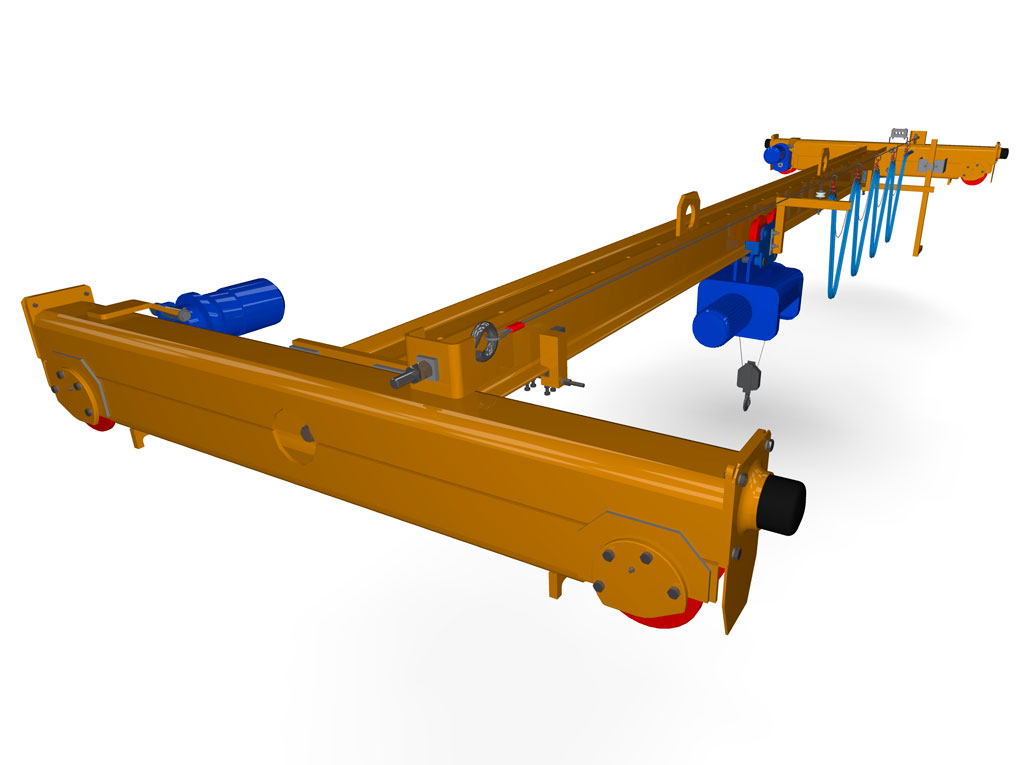

A special overhead crane equipped with a traverse with a flexible and rigid suspension of the traverse, which is designed for lifting operations with long-measured profiles or sheet metal, pipes, fittings, and constructional structures.

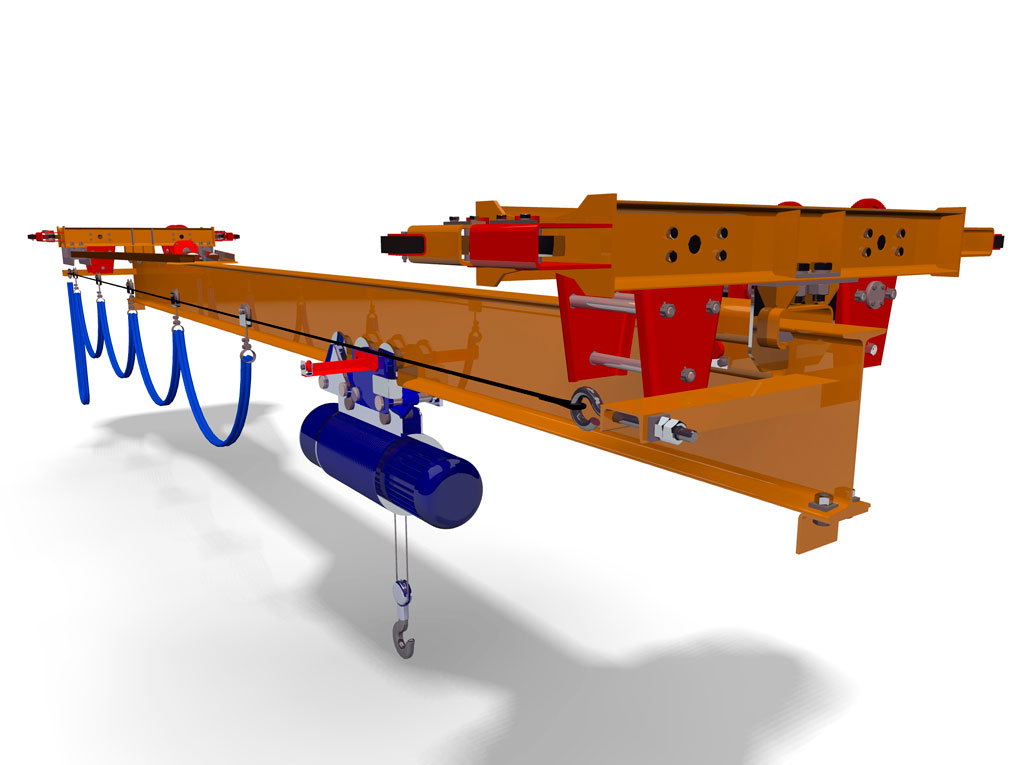

The cranes are manufactured as serial or can be produced customized according to the customer’s specifications. They are based on a proven reliable design and controlled from a stationary or suspended to the trolley cabin. The crane lifting mechanisms is arranged according to the conventional expanded (detailed) scheme, with a winch lift, and are equipped with crane electric motors with phase and squirrel-cage rotor, gearboxes and brakes of domestic production. The mechanisms of travel of the crane, trolley, rotation of the upper part of the trolley can be manufactured with the drives of the mechanisms using geared motors from the best European manufacturers.

Electric drive control systems: relay-contactor or frequency types. Cranes with magnetic traverses are equipped with magnet control systems and uninterruptible power sources. Control panels for cranes are equipped with command controllers or joysticks, as well as with control panels with visualization of the state of electrical equipment.

The shunt to the cranes can be both types: trolley (open and closed) and cable (on a rigid profile, cable drum, cable chain). The shunt to the trolleys can also be trolleys-types (open) and cable (on a string, rigid profile, cable loop, cable chain). The cranes are manufactured with maximum unification of assemblies, parts and adopted design solutions.

The field of application of the overhead cranes with a traverse

Traverses are used where it is impossible to use slings due to lack of lifting height or where significant tensile forces arise in the slings, bending stresses in the lifted cargo and/or fasteners. Overhead cranes with a rigid suspension of the traverse are widely used in metallurgy, in open-hearth, rolling and forging production.