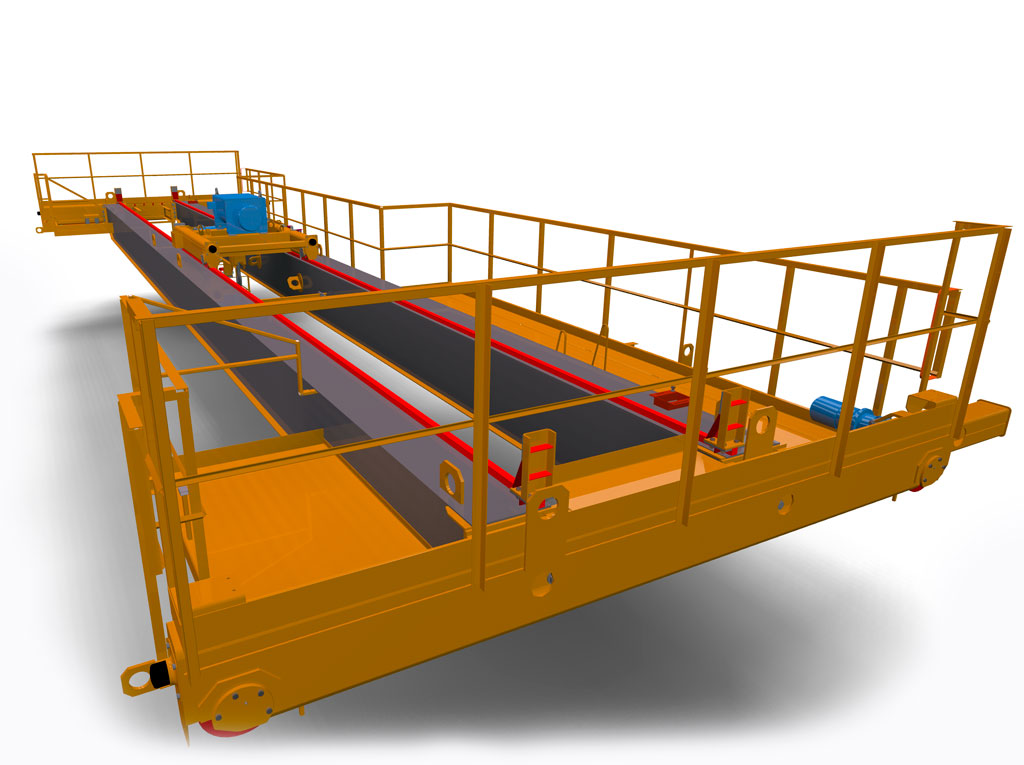

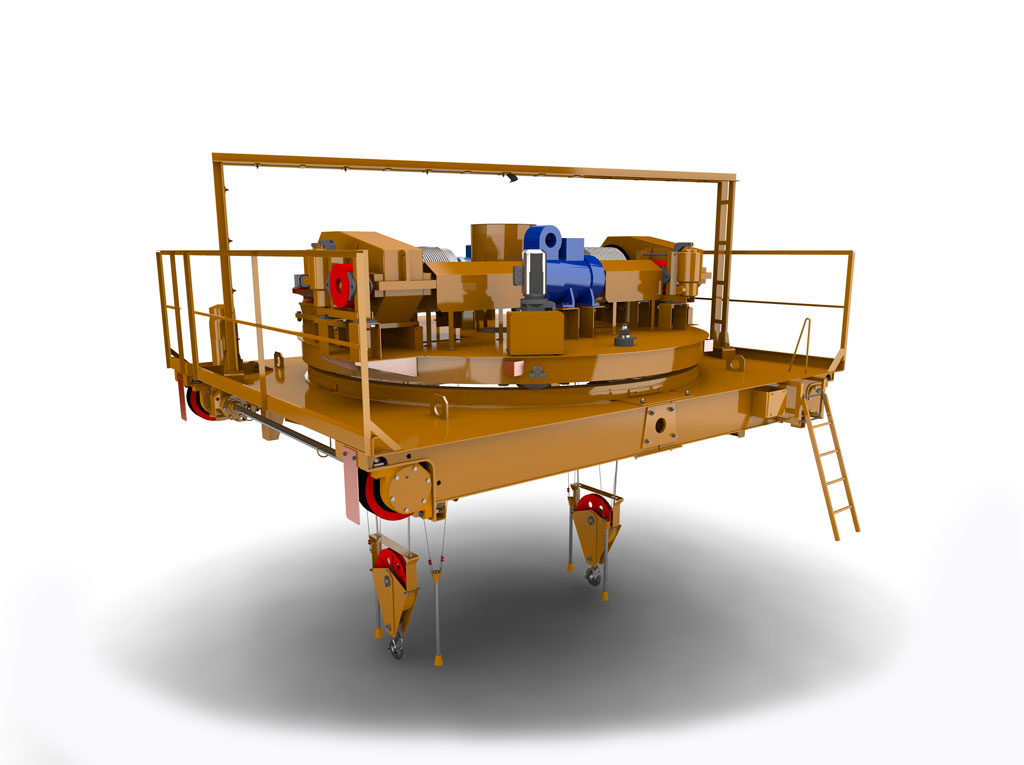

The double-girder overhead crane from the Vira-Service Intermash plant is sample of the best engineering development of the enterprise!

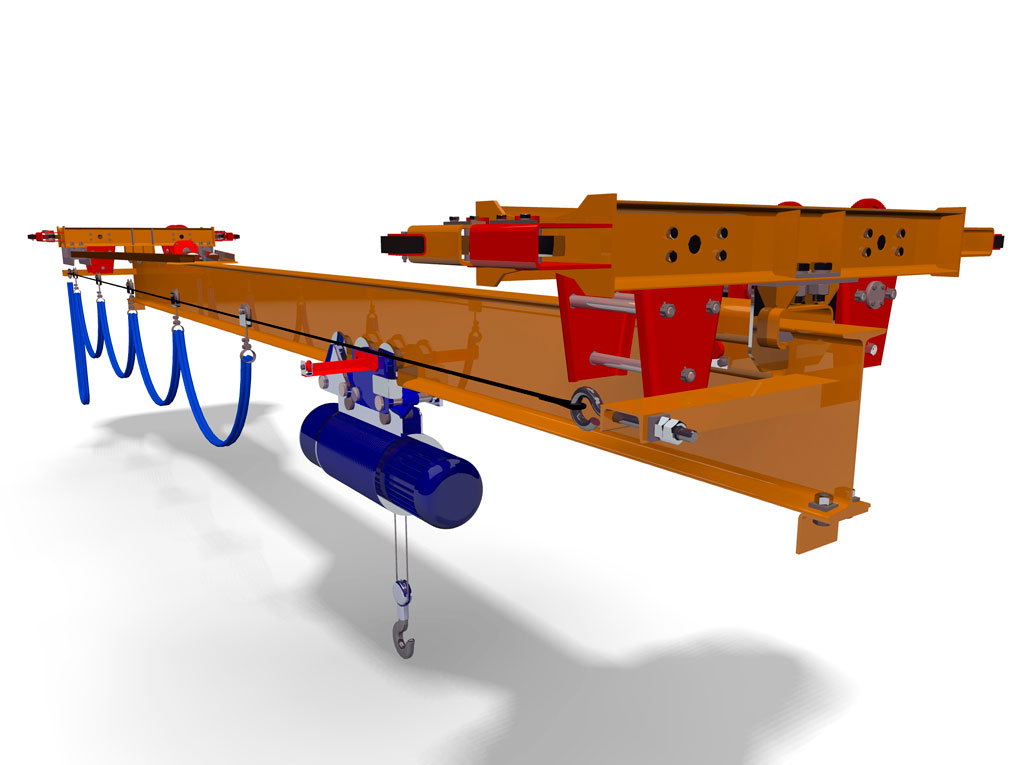

This hoisting equipment is the embodiment of power and ease of use! A budgetary and at the same time reliable and safe crane. It can be controlled from the cabin, by a pendant controller from the ground or through radio channel. The lifting mechanism on these cranes is featuring very compact structure based on stationary hoist from the best European manufacturers.

Crane travel mechanism and trolley are also very compact with usage of gear motors with built-in brakes also from the best European manufacturers. Control systems for such drives, usually, are based on the use of frequency converters and allow to ensure smooth start-up and braking of the drive, which significantly reduces the dynamic loads on the mechanisms and increases their durability.

Shunts of the cranes can be both: trolley (open and closed) and cable (on a rigid profile, cable reel, cable chain). Cable trolleys’ shunts are done on a rigid profile Festoon type. In accordance with the customer’s request or according to the operating conditions, it is possible to install a contactor-relay control system.

Application of double-girder overhead cranes

The versatility of the structure and a wide range of application make the double-girder overhead crane demanded in various industries: in workshops, warehouses, during dismantling works, construction and repair works for lifting and moving loads of various weights and dimensions. The crane can operate as outdoors at low temperatures as well as at foundry workshops. The double-girder overhead crane is also suitable for transporting goods heated above 300 ° C (for example, molten metal), poisonous, explosive substances.