Lifting and Transport Equipment Plant Vira-Service Intermash offers for your business a rail-mounted gantry container crane (RMG). This innovative design is the result of many years of work in the field of design, manufacture and installation of lifting and transport equipment. Our experience in technical solutions takes into account all aspects important for our customers. You can always be sure of the reliability and performance of our RMG cranes. Accuracy and simplicity of control, low level of energy consumption and small maintenance costs are significant advantages of rail-mounted gantry container cranes produced by “Vira-Service Intermash”.

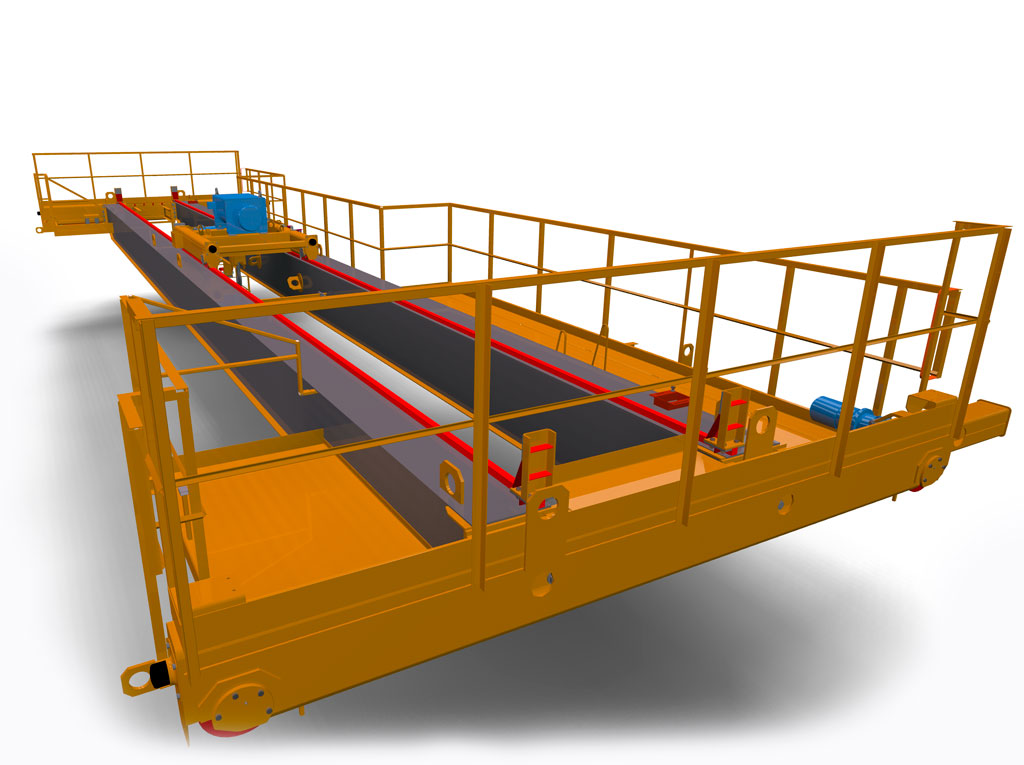

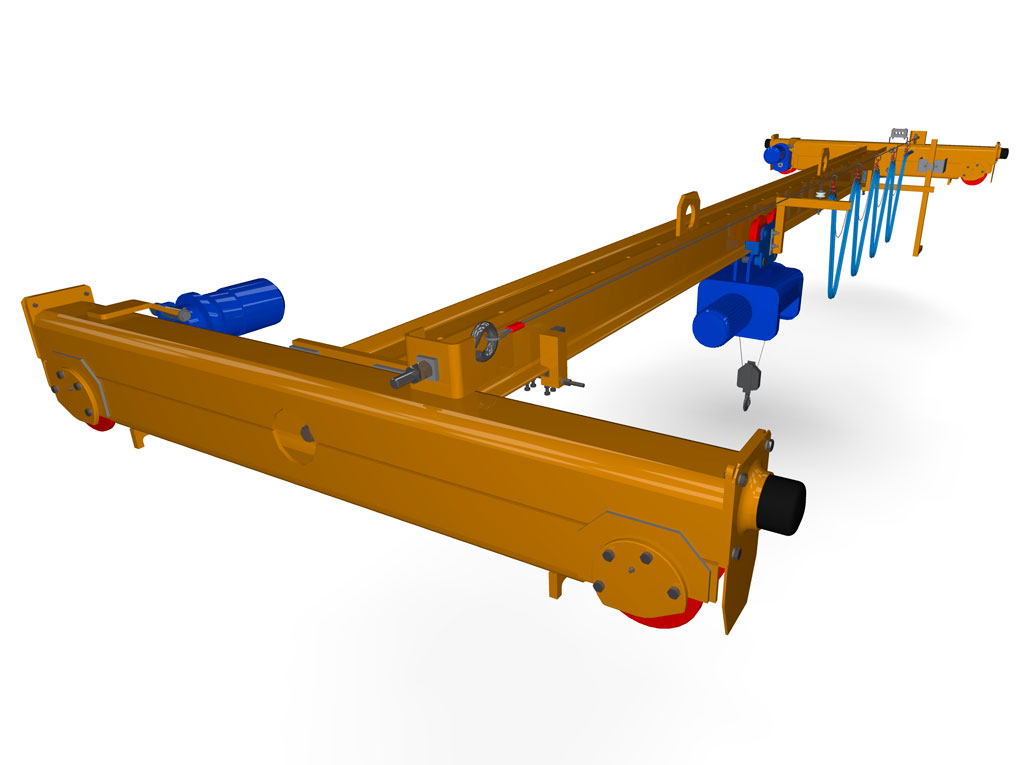

Depending on the operating conditions of the crane, its metal structures can be lattice or box-type, cantilever and double-cantilever, with a swivel or non-swivel trolley, for different climatic conditions.

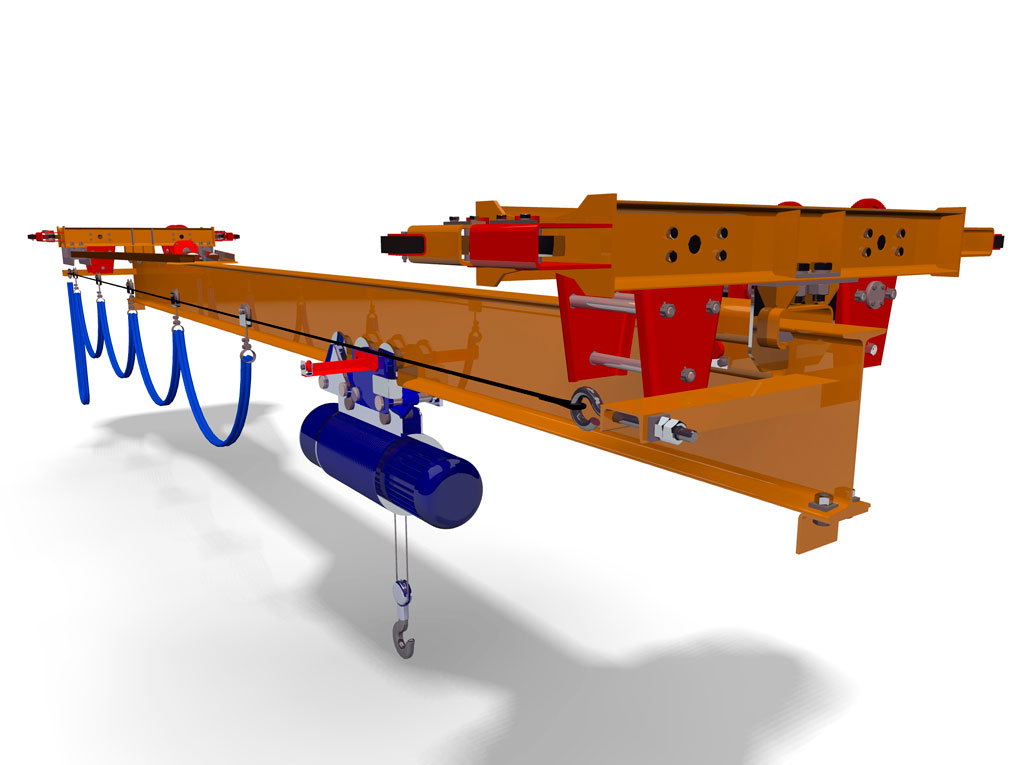

Cranes manufactured by Vira-Service Intermash are equipped with a frequency control system Siemens and Schneider Electric, as well as SEW Eurodrive and Danfoss drives.

The container crane is equipped with load-grabbing devices of automatic action. Control is done from the crane operator’s cabin, but sometimes the cranes are made with semi-automatic or manual grabbing of the load.

All cranes manufactured at our enterprise meet the basic safety requirements and equipped with a pressure alarm, a device against rail gripping, a load limiter.

Area of application of gantry container cranes

A gantry container crane is an integral piece of equipment for any road or rail terminal. The sea or river port will also not be able to work without it, because the main function of all types of container cranes is to load and unload containers from vehicles to terminals and vice versa.

Sea vessels can also be equipped with cranes, making them independent from port capabilities.